In English it is also the plural form of ‘ant’. The ant is perceived as a social insect, strong in relation to its size, hence the features of an industrious ant can also be determined in the ANTS concept. There will be some nine billion people living on the globe in 2050 while the area available for arable crops will be less than today. Farmers will need advanced technology to feed this expanding population, and will be producing energy in addition to food.

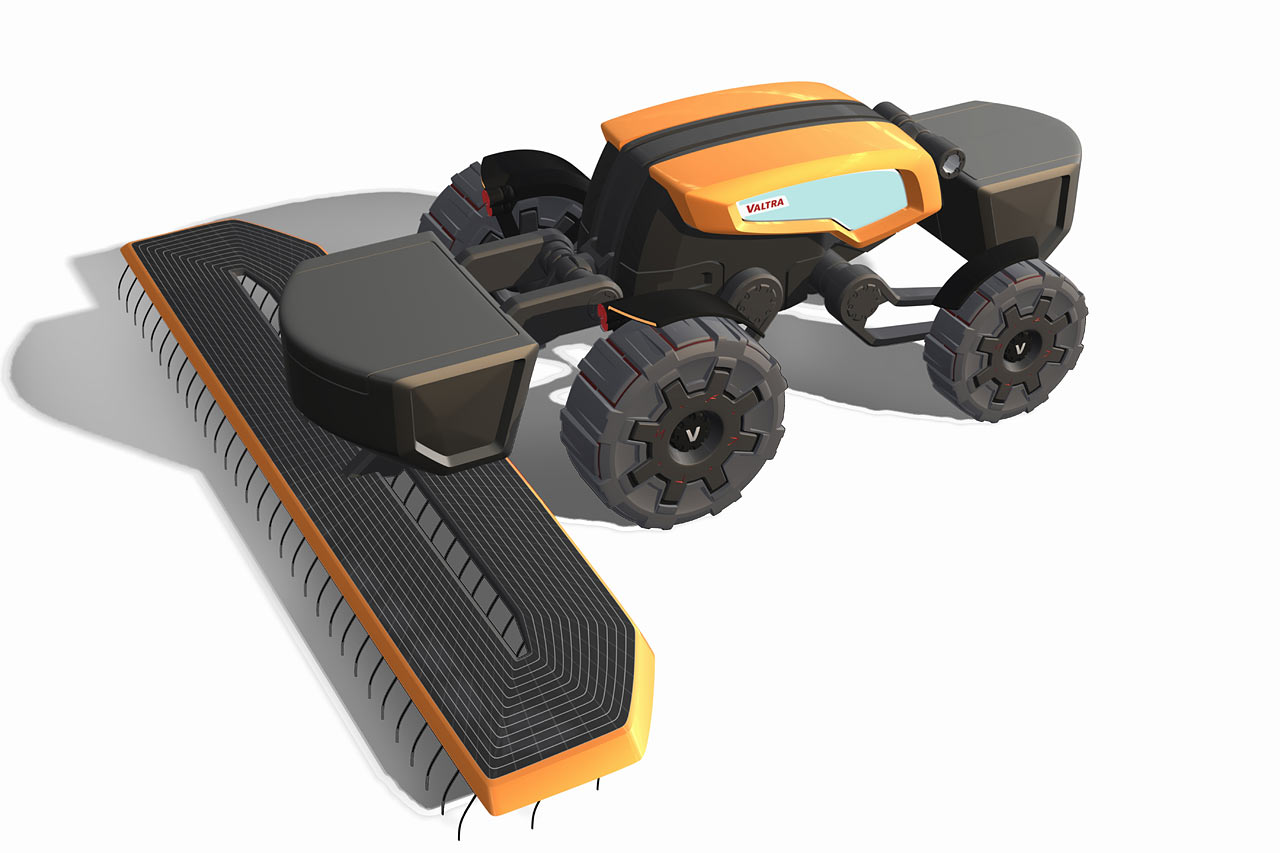

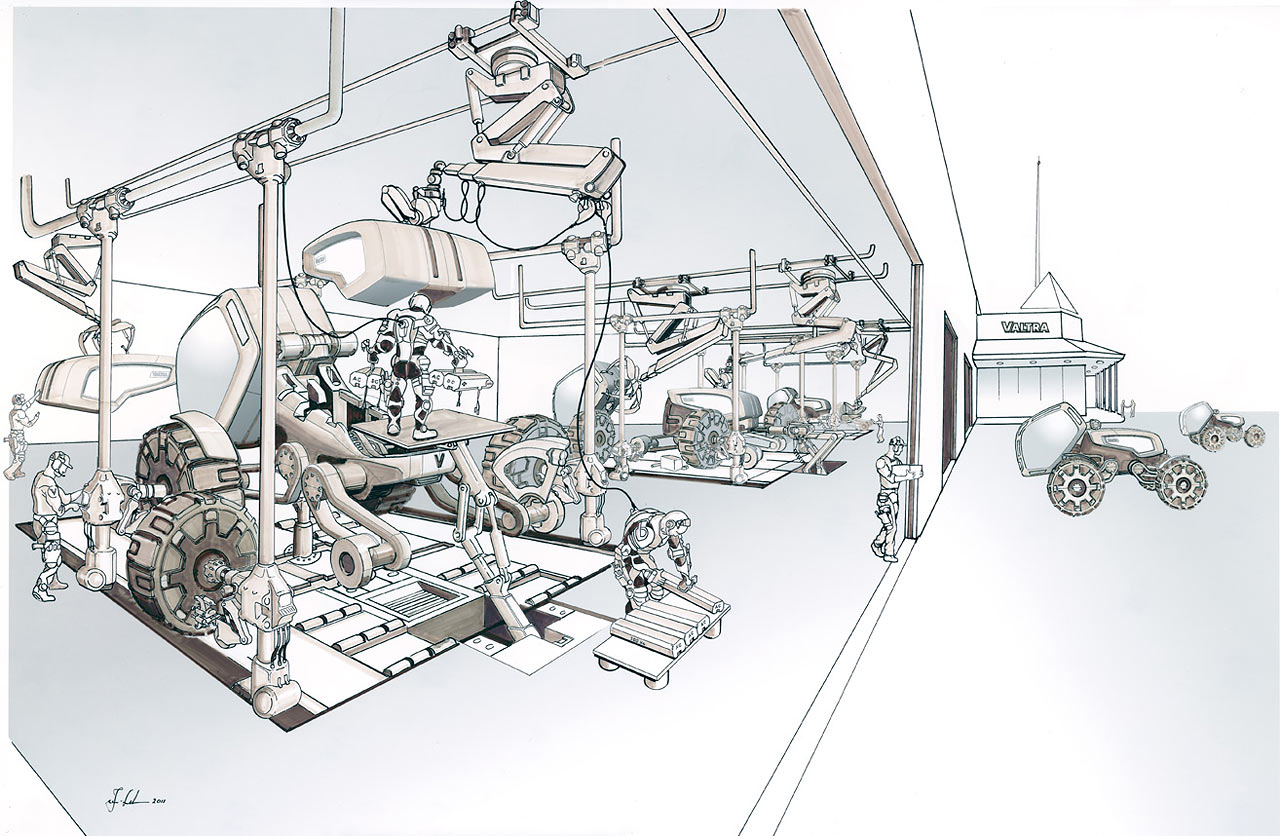

ANTS is a modular solution. It comprises two basic modules: The soldier, with a power of some 100 kW, and the worker, with a power of 200 kW. Both can act together or work individually. For supervisory tasks there is a cab that can be fitted onto both machines. When executing heavy work requiring the participation of an operator, the modules can be interlocked i.e. the rear wheels are adjusted to a narrow track while the front wheels of the other machine are moved abreast and the machines interlocked. In this mode a queen becomes available, with articulated steering and maximum power of 400 kW. The cab is a capsule that can be attached to both basic modules. It can rotate and may be placed at the front, rear or on top of the basic module. The cab may be lowered for safe access; most tractor related accidents occur when getting in and out of the cab.

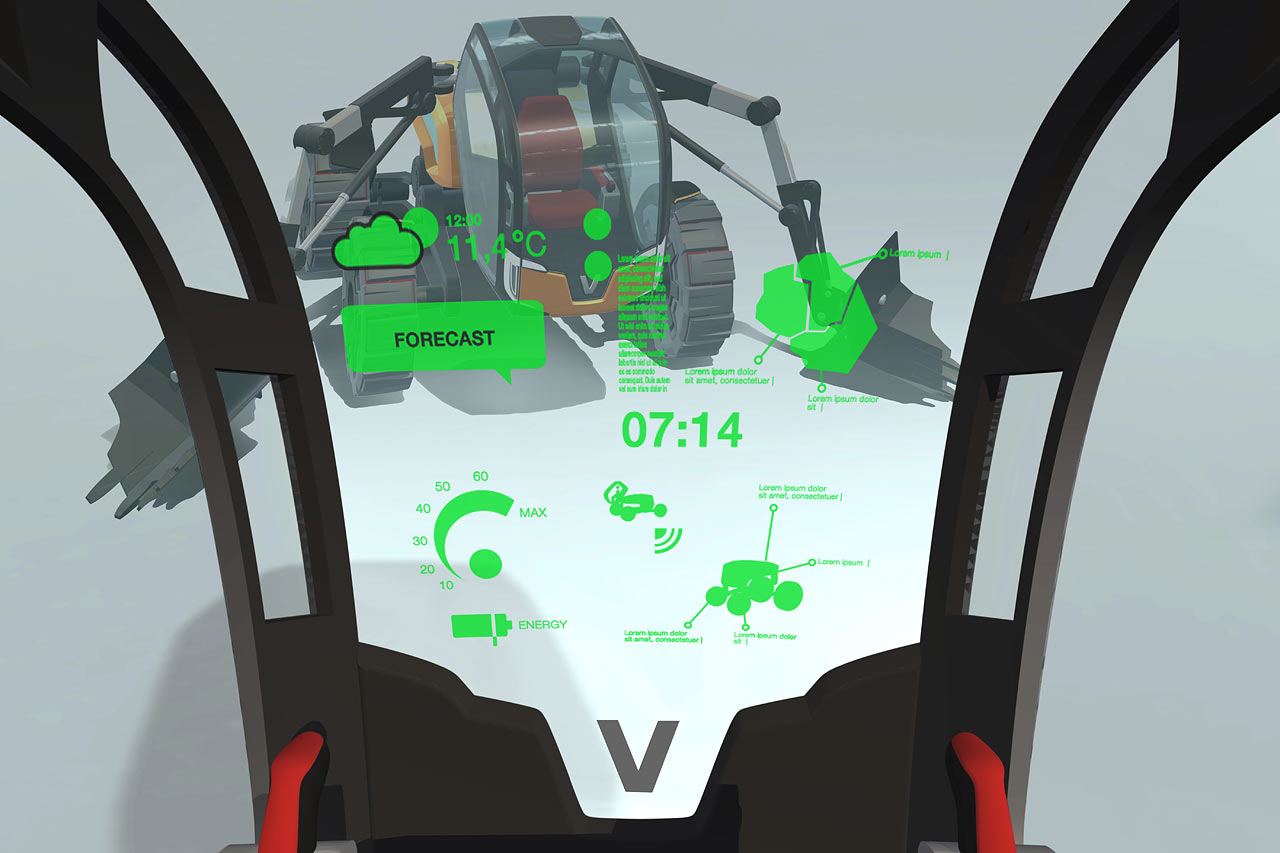

The operator’s interface is as simple as is possible with the bulk of the commands given by speech. Information that is important for the task in hand is superimposed as a HUD (heads up display) on window surfaces. The machine has excellent communication abilities. The composite structure of the cab is safe, and you will have an unrestricted view in all directions. The traditional Valtra feature TwinTrac has been developed to its maximum, because the mobile cab means the ANTS concept has no distinct front or rear.

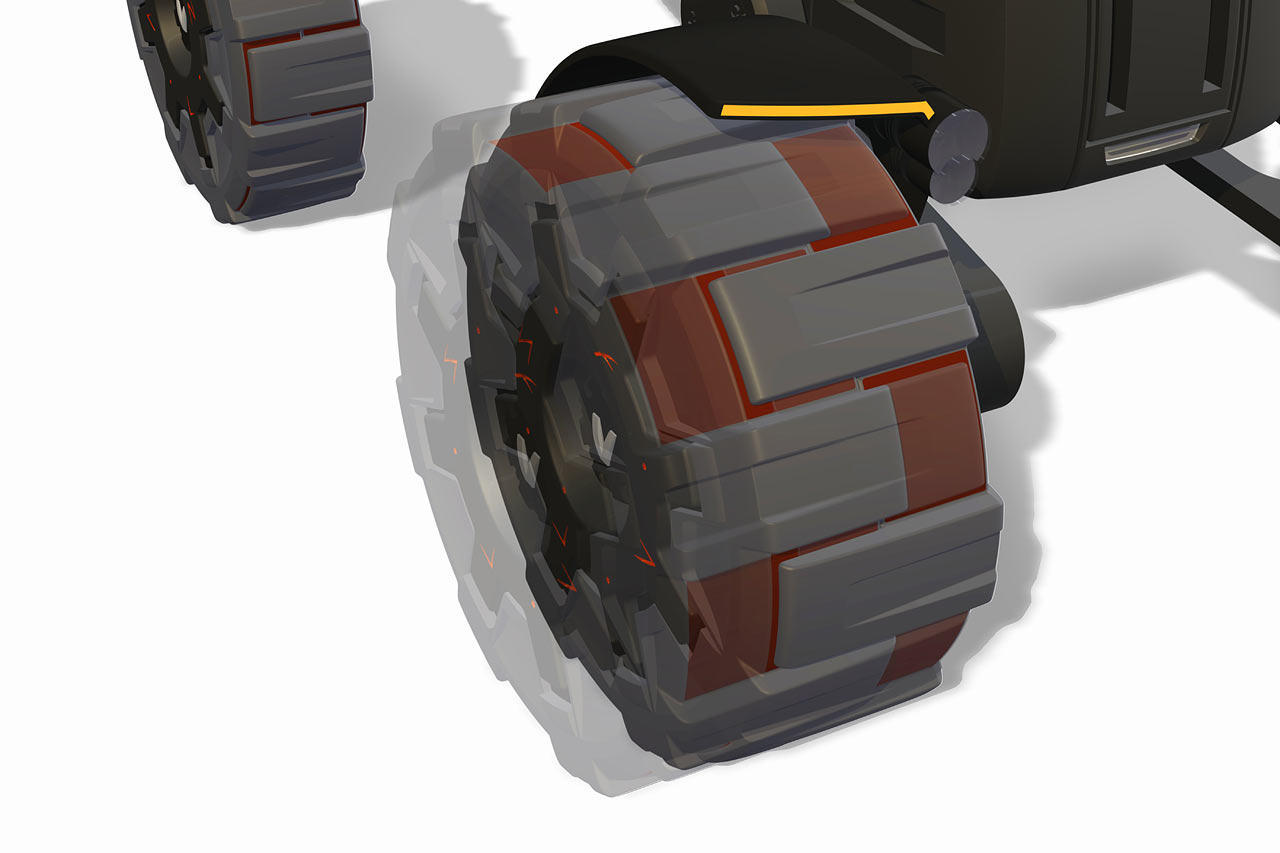

Energy technology will make huge leaps during coming decades. The transmission will be electronic and electricity will be produced in various ways: through efficient batteries, fuel cells and turbo generators, or through a highly efficient internal combustion engine that can exploit biogas or bio diesel produced on farms. The power source will have the potential to be changed in a modular way as the need arises. The structure of the basic machine will be light. Wheels will be set at the end of shafts which are also utilised for active suspension and ground clearance adjustment as well as for lifting and lowering implements from and into the ground. Minimum clearance is designed for on-road travel; providing the greatest possible stability. Large clearance is utilized off-road. The wheels are smart, and their width, or the size of the contact surface, can be adjusted to avoid soil compaction. ANTS will examine soil structure and composition, and automatically optimize its contact footprint with the ground. As the wheels broaden, the pattern will become more aggressive. However, the wheel surface will be optimized for on-road driving in the narrow position.

The worker is in the 200 kW power class, and will be able to carry out tasks unattended. The default soldier is equipped with a cab, and will carry out all farm centre service tasks. Therefore it is equipped with a rail like spinal core, where different kinds of implement can be attached. It will also be easier to gain access to low and tight places with the machine, thanks to its ability to ‘curtsy’. The majority of the implements will be managed by electric motors and actuators. Should traditional hydraulics be required, the oil will be aqueous. The structural frame is a rail that runs from front to back. The cab and working equipment can be fixed onto this rail.